BRUSH Power Generation

Categories

System & Instruments,

Description

BRUSH Power Generation was acquired by Baker Hughes in 2022. The added products and services fuel BH’s electrification drive through providing top quality Generators, Synchronous Condensers, Synchronous Motors, Excitation systems & automatic voltage regulators (AVRs), Power management systems (PMS), Generator control and protection (GCP), Generator line and neutral cubicles (GTC) ,Auxiliary control and monitoring.

The BRUSH™ Power Generation division provides reliable and innovative solutions to meet the most challenging requirements for power generation, grid stabilization, substation and power grid support, and decarbonization through electrification.

Generators

With over a century of experience, knowledge, and innovation embedded in the designs, our electric machine configurations are custom engineered to meet unique operating conditions for utilities, packaged mobile, FPSOs, offshore, and renewable applications like geothermal and concentrated solar plants.

PRISMIC excitation systems

The PRISMIC A3100 includes two fully featured independent controllers and two independent power circuits in a single 6U, 19-inch enclosure, all available as removable cards (single channel option available). The A3100 builds on decades of experience and technologies, incorporating features such as integrated power system stabilizer, automatic synchronizer, R10 ground (earth) fault receiver, ethernet and USB connectivity integrated into a single standard 19-inch rack package. With most connectors completely compatible with earlier controllers, the A3100 is an easy replacement choice for MAVR, MicroAVR, A30, A32, and other previous AVRs.

The PRISMIC A32 excitation controller or automatic voltage regulator (AVR) includes two fully independent controllers and two independent power circuits. It is one of the first excitation controllers to provide features such as an integrated power system stabilizer, a color TFT display, and ethernet connectivity. It is mounted within a single 6U, 19-inch enclosure.

The PRISMIC A12 excitation controller, designed to control the excitation of a brushless generator, uses the latest digital microcontroller technology to make it our most compact unit. It’s provided on a mounting plate, complete with wiring loom and auxiliary equipment.

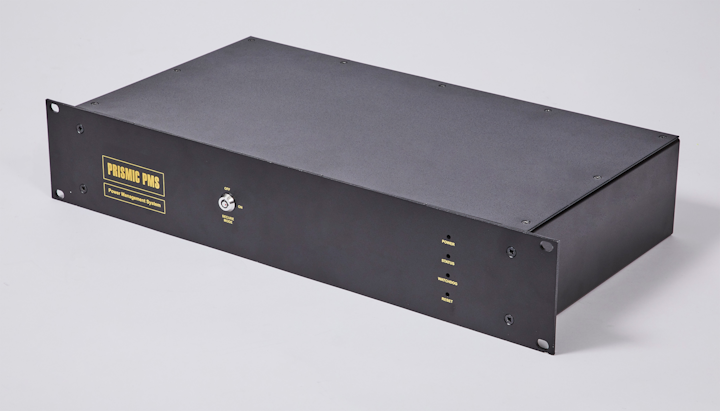

PRISMIC power management systems (PMS)

With a robust design continually evolved over 30 years, our BRUSH™ Power Generation PRISMIC® power management system (PMS) is an extremely powerful and flexible safeguard against power outages and the related disruption and cost. It’s a comprehensive solution for any industry, location, or application—from oil platforms to financial data centers.

Each bespoke PRISMIC PMS is tailored to meet your specific organization and site requirements, and power system topology, with all design data meticulously controlled and recorded. It therefore avoids all the limitations of generic PLCs or off-the-shelf equipment modules.

PRISMIC is easy to use—with a fully featured Windows-based interface to navigate through the comprehensive range of displays and settings.

Designed with IEC61850 at its core, PRISMIC provides interoperability with IEDs from all manufacturers, simplifying system integration and limiting the need for custom communication protocols.

Extremely rapid intelligent load shedding (ILS)

ILS can be initiated in less than 10 ms, and our algorithms ensure that only the minimum number of load feeders are tripped—minimizing disruption to operations.

Load priority assignments are easily adjusted by operators using the HMI software, or automatically using intelligent algorithms, to best fit individual plant operational needs.

Controlled load reduction is also possible to avoid the need for load shedding, for example by reducing thruster pitch.

Gradual-overload, under-frequency, and rate-of-frequency-change load shedding functions are also provided to protect the power system from a cascade failure and blackout.