Safety Services

Hima Safety Services

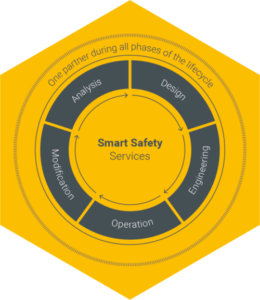

HIMA Smart Safety Services give you flexible, scalable support from a single partner for the entire safety lifecycle. Our experts support you throughout your plant’s lifetime, and help you define, install, and operate your systems in line with current safety standards. We always consider the safety lifecycle as a whole, which allows us to create optimal, cost-efficient safety solutions – so you can focus on your core tasks again.

Safety is not a one-off initiative or a quick and permanent fix – it is a continuous, dynamic process. Ensuring the safety of your industrial plants requires you to examine the whole picture. You need to consider the entire lifecycle of your safety system: from planning and installation to operation and modification. Even the eventual decommissioning of the system should be taken into account.

Putting this strategy into practice requires significant effort and extensive knowledge. HIMA is on hand to support you from the very start. We offer specialized services to give you peace of mind throughout all phases of the lifecycle – so you can focus on your core business. With help from our experienced safety engineers, you can ensure safe plant operation and minimize downtime.

When you talk with HIMA, you are not just talking with the sales team. You are talking with engineers. With technicians who understand your challenges and work out a solution that fits your company, together with you. For over 50 years, we have been focusing on safety-related automation solutions. Now you can benefit from this technical expertise – in every phase, right from the start.

We not only develop, we also implement. As soon as the specification meets your requirements, our programmers, planners, and control panel wiring technicians get to work, and we integrate our HIMA systems in your entire plant. Hardware and software are developed in parallel, led by a project manager who remains your single point of contact throughout all project phases. Appropriate for your scope of delivery, the results are first integrated in an overall system in our own test facility and subsequently tested.

Whether it’s a small project or mega-project: we can help. We have implemented over 40,000 customized safety solutions worldwide. In every project we keep our promises – in terms of finances and time frames. We rely on our worldwide engineering network, as well as specially trained system integrators. As a result we can handle situations with even greater flexibility and always within budget. The result? Every single HIMA engineering project undertaken has been successfully completed.

Safety is not a one-time affair or a quickly implemented permanent solution – it is a continuous and dynamic process. Therefore, it is important to consider the overall lifecycle of the plant from the initial analysis through planning and installation to operation and retrofitting or modernization. In this way, you reduce the costs incurred and minimize the safety risks, avoidable downtime and unexpected follow-up costs over the entire lifecycle. This ensures the reliability, availability and performance of your plants.

Sometimes, you just have to be there. Close collaboration, constant communication, and a local presence are extremely important to the success of any safety engineering project. Whether you require assistance with the installation or modification of your safety systems, or are looking for a spare parts supplier you can count on, our experts are there for you. Let us join forces to ensure your plant runs safely, efficiently, and profitably.

Every business, industry, and processing plant has its own unique challenges. So when it comes to service agreements, a one-size-fits-all approach will often lead to unnecessary costs. At HIMA, we understand that no two industrial plants are the same. That’s why we give you the freedom to pick and choose the services you really need. In this way, you keep your costs to a minimum, maximize plant reliability, and always comply with safety standards.

Plants are becoming increasingly complex. At the same time, the risk of cyberattacks is rising. That’s why automation security is now one of the most important criteria for the configuration and management of your safety instrumented systems (SIS). As a plant operator, you are also responsible for ensuring that your SIS fulfills security requirements. Often, however, a lack of time and resources presents a challenge.

This is where the SIS Security Check from HIMA comes into play. Experienced, impartial safety experts perform an on-site assessment of your security measures, SIS configuration, and network components. You receive an overview of your safety system’s status as well as security risks and vulnerabilities. This helps you identify which measures you should take.

The safety and availability of your industrial plant is a top priority for you. When a new plant is built, safety instrumented systems (SIS) are designed and commissioned by safety specialists. During the course of their life cycle, every upgrade or modification requires a review of functional safety with regard to the applicable standards and norms, e.g. IEC61511 Ed. 2. The current status of a plant in terms of safety is not always well documented. Each plant operator is responsible for ensuring that the SIS meets the safety requirements. How can this be remedied if there is a lack of time and resources?

HIMA solutions can be combined with distributed control systems (DCSs) from all leading providers. At the same time, they run independently and are physically separated from the DCS.

Our dedicated DCS competence team continuously tests all integration options, documents them in detail, and develops efficient, pretested configurations. They can share their expertise and consult you on the best course of action. Furthermore, if you require support on DCS integration, our team will be happy to help. For a full overview of our DCS integration solutions, including a comprehensive list of integration options with leading DCSs.

Excellent support requires a wealth of knowledge and expertise. With HIMA, you can draw upon over 50 years of experience. Whatever industry you are active in, our safety experts will support you. We offer a range of customizable service agreements to provide you with round-the-clock assistance.