Eaton

MTL, part of Eaton’s Crouse-Hinds portfolio

is a leading global provider of intrinsic safety explosion protection and surge protection devices for use in process control applications. Eaton provides one of the world’s largest portfolio of electrical equipment for explosive, classified, and industrial areas.

MTL 9460-ET intrinsically safe ethernet products

The Crouse-Hinds series MTL 9460-ET product range provides cost-effective Intrinsically Safe (IS) Ethernet equipment that can be installed and maintained easily in hazardous areas. The intrinsically safe hazardous area certification permits the components to be mounted in a Zone 1, or Division 1 hazardous area with connectivity into Zone 0.In Process Automation it is also preferable to use a single cable to provide both power and communications to the end device. The 9460-ET range can deliver Intrinsically Safe Power over Ethernet (PoEx™) with a single Cat 5e or Cat 6 cable, allowing live connection and disconnection of the end device in Zone 0 and 1 hazardous areas.

MTL Configuration Tools and Software

The PCS45/PCL45USB configurator allows our converters to be configured from a standard PC running a Microsoft® Windows® operating system. It comprises PC software, provided on a CD (PCS45), and an ATEX certified interfacing link (PCL45USB). Converters can be configured from the safe area, while on-line, and configurations can be saved to disk and printed out when required. It is suitable for use with Crouse-hinds series MTL4000, MTL4500, MTL5000 and MTL5500 range.

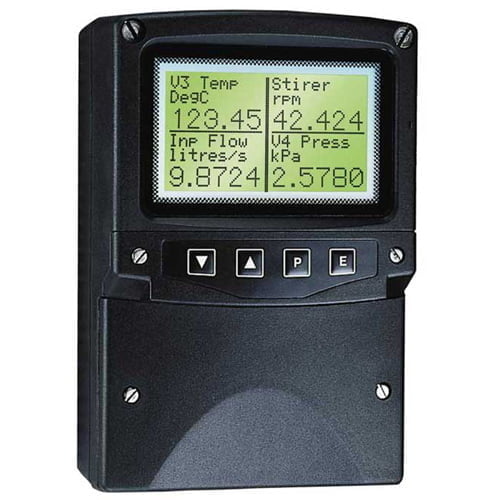

MTL Fieldbus Display Systems

The MTL range of intrinsic safety fieldbus displays are designed to display process variables, in text or simple graphics, and provide a low cost operator interface in a safe or hazardous area.

MTL have the widest range available, from 8 variable to cost effective single variable version, field and panel mount variants, safe and hazardous area version as well as FOUNDATION fieldbus™ H1 and Profibus PA versions. All versions are bus powered to simplify installation.

MTL intrinsically safe power supplies

Eaton’s Crouse-Hinds series range of MTL intrinsically safe (IS) isolated power supplies are ideal for providing power to instrumentation in hazardous process areas. They offer a wide range of different IS output voltages, ranging from 4.8V – 17.7V, offering flexibility of options to best suit a variety of applications.

491-PS-PLUS models: Safe area / Zone 2 mount power supply that takes standard 24V DC input and produces an intrinsically safe, 12V DC nominal output. Capable of powering the Ethernet modules and other IS devices- with Ex ia output (up to 200mA) for devices mounted in Zone 0, and Ex ib output (up to 400mA) for devices mounted in Zone 1 Gas Group IIB hazardous areas.

9492-PS-PLUS models: Safe area / Zone 2 mount power supply that takes standard 24V DC input and produces an intrinsically safe, 12V DC nominal output. The optimum solution for powering MTL 947x-ET/G Ethernet modules and other IS devices- with Ex ia output (up to 200mA) for devices mounted in Zone 0, and Ex ib output (up to 400mA) for devices mounted in Zone 1 Gas Group IIB hazardous areas.

MTL 9493-PS models: Safe area / Zone 2 mount power supply range that takes standard 24V DC input and produce intrinsically safe, 5.4 to 18V nominal output. With Ex ia output for devices mounted in Zone 0 and Zone 1, Gas Group IIB and IIC hazardous areas.

MTL SUM5 Smart Universal Marshalling

Minimise CapEx and maximise investment return with the revolutionary smart universal marshalling solution, SUM5. MTL SUM5 combines five functions in one modular design enabling one standard cabinet to deliver the lowest lifetime costs and lowest installed cost while saving valuable space in a control room.

MTL SUM5 offers a single cabinet design, with ‘plug and play’ configurable modules for the five key marshalling functions. This eliminates the need for intricate wiring to interconnect the components, ultimately improving uptime and reducing the cost of wiring, installation and maintenance.

MTL4500 Backplane Mounted Isolator

The MTL4500 range of backplane mounting intrinsic safety isolators offers an innovative solution for protecting electrical signals in potentially flammable or other hazardous areas. Helping to ensure a safe work environment and protects those nearby from explosion risks.

With industry leading features and performance in a single package, MTL4500 utilises innovative planar transformer technology at its heart and extensive automation in construction. It is designed with the requirements of system vendors in mind, for ‘project focussed’ applications such as Distributed Control Systems (DCS), Emergency Shutdown Systems (ESD) and Fire and Gas monitoring (F&G).

With fast module installation, easier system integration, improved performance from low-power circuit designs and more I/O channels in each module giving the highest packing density on the market plus 3 port isolation as standard.

MTL5500 Din-Rail Mounted Isolator

The MTL5500 range of intrinsic safety isolators are designed to meet the needs of the IS interface market for application focussed projects, from single instrument loops to fully equipped cabinets. Protecting electrical signals in potentially flammable or other hazardous areas. Helping to ensure a safe work environment and protects those nearby from explosion risks.

MTL5500 range has a slim, compact housing to suit a variety of space requirements and the range of module options contains both single and multiple channel devices which enables the user to choose the functionality and integrity needed without sacrificing cabinet space. The modules can be used for a wide variety of interface tasks for process instrumentation.

All signal wiring is made through removable connectors which facilitates fast installation and simple maintenance procedures.

MTL660 Loop Powered Indicators

The MTL600 range of digital indicators enable process variables to be displayed locally in hazardous and general purpose plant areas. A typical example would be the re-transmission of mass/flow computations from the safe area, through a suitable MTL IS interface to the indicator in the hazardous area.

The displays are loop powered from the 4-20mA process signal and their low voltage drop allows them to be installed in almost any 2-wire, 4–20mA transmitter loop. All units can indicate measured values in a linear or a square root extraction mode; the latter being used, for example, to display flow from differential pressure measurement devices such as orifice plates, Dall tubes, or venturi.

The MTL661 Field mounting unit is housed in a tough aluminium enclosure, suitable for wall or pipe mounting. For corrosive atmospheres use the MTL663 – the plastic case provides excellent resistance to harmful contaminents.

The MTL665 is the panel mounted version and is IP65, IP66, IP67 and NEMA4 rated.

MTL66x IS indicators are classified as ‘non-energy storing’ simple apparatus so they can be inserted into any IS loop without recertification.

MTL7700 Din-Rail Mounted Barrier

Known for its quality and reliability, the MTL7700 range of intriniscally safe passive network devices use Zener diodes, resistors and fuses to safely divert excess electrical energy to ground and prevent sparking or overheating of equipment in hazardous areas. Helping to ensure a safe work environment and protects those nearby from explosion risks.

As a DIN rail mounting barrier, the MTL7700 provides quick and easy installation without the need for special hardware. Removable terminals are used for ease of installation, maintenance and for providing a loop disconnect by simply unplugging the terminals from the side of the module. Wire entry is also angled to assist wiring within limited space enclosures.

MTL7700 barriers clamp simply and securely onto standard T-section DIN rail, simultaneously making a reliable IS earth connection.

For applications where field power is required for switch inputs or 2-wire transmitters, the MTL7700 range provides a bussed power feed facility. When used in conjunction with the MTL7798 power feed module the user has a fully protected, electronically fused supply to many barriers with no additional wiring required.

MTL830C Temperature Multiplexer system

The Crouse-Hinds series MTL830C multiplexer system with Modbus® outputs provides a cost-effective alternative to single-loop isolation. The cost of installed wiring is reduced by up to 50% by communicating the input of multiple hazardous-area sensors over a single twisted pair data highway. Further savings are achieved by reducing the number of inputs to the host, which improves cabinet space and weight. A multiplexer transmitter, mounted in the hazardous area, caters for thermocouple, RTD and mV analogue inputs.

Two compatible safe-area receivers provide easy integration of Modbus® outputs into PLC, PC or DCS controllers. The MTL838C Modbus RTU receiver supports redundant serial interfaces and the new MTL838C-MBT Modbus TCP receiver supports Ethernet connectivity.

FCS-9616/9632 MTL Process Junction Boxes provide ideal enclosures for mounting MTL831C temperature multiplexer transmitters in harsh and hazardous environments. They offer plenty of space for termination and wiring, making it easy to install and maintain the fieldbus system.